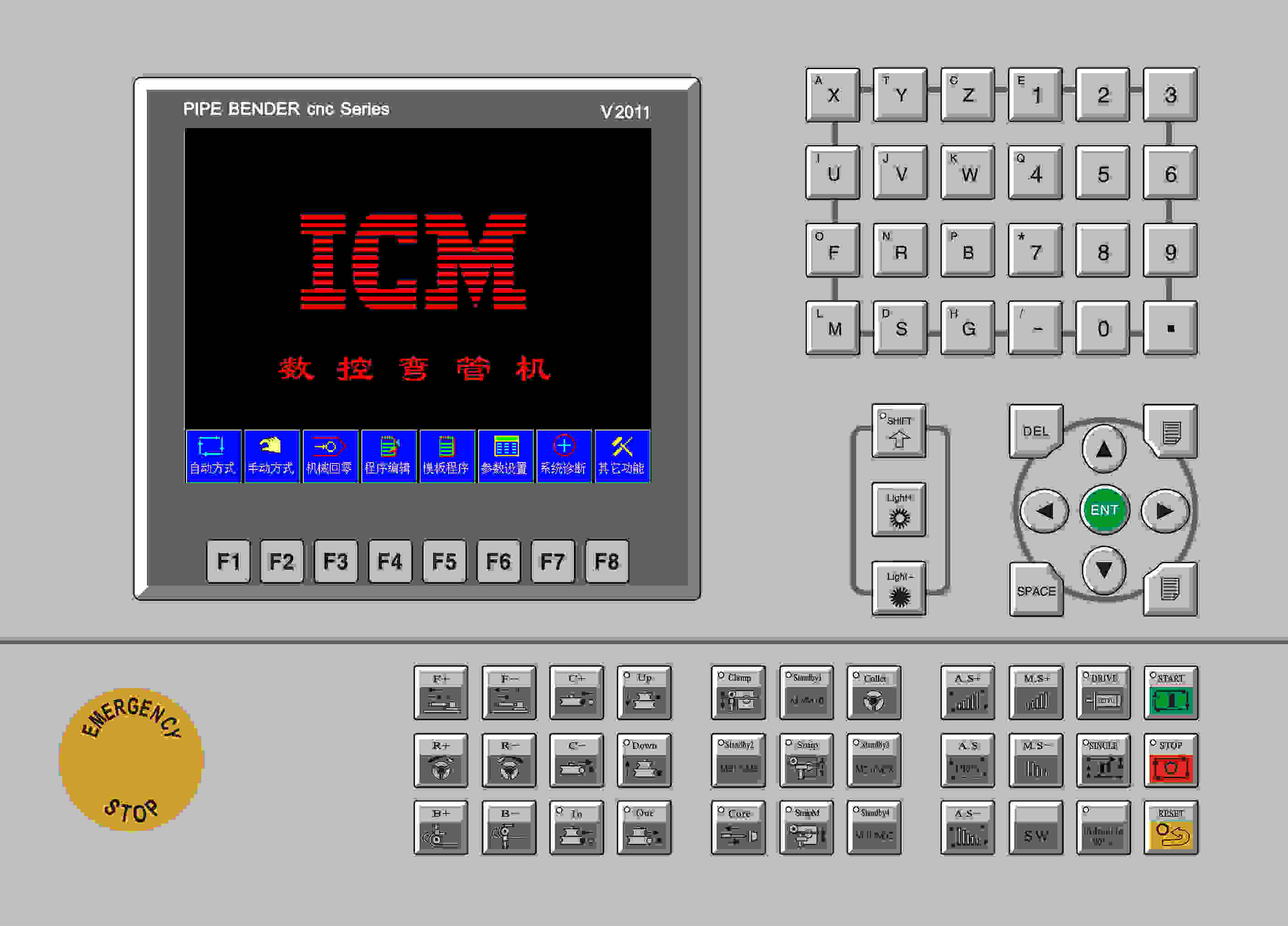

ICM-800W CNC tube bender system

● using industrial-grade ARM + DSP processors, high-speed, high-precision control.

● using the best industrial structure, strong anti-interference ability, high reliability, the average length of the fault period.

● The maximum number of controllable axes: 8 axes, the maximum number of axes linkage: 8 axes.

● Widely used in bending machine, feeder, pipe end machine, bending machine complex process control.

● System interpolation cycle 0.2ms, control precision 0.01mm / 0.001mm optional.

● The maximum speed of 120 m to quickly locate / min (control accuracy when 1μm), the maximum feed speed 60 m / min (control accuracy when 1μm).

● with 1000 / second program instruction processing capability, the pre-2000 instructions, enabling high-speed small segments, processing spline curve.

● The system provides 100 to 400 processing program storage space, providing unlimited storage space and processing program through the U disk.

● Provides coordinate programming, motion programming, code programming a variety of programming.

● provide a template editor function, you can customize the template program to meet individual requirements.

● has entrusted feed detection function detects the position of prop material can be set.

● Rich movements M commands, the delay can be set after each operation.

● zero offset, zero position coordinates can be set, positioning speed, feed rate, acceleration and deceleration time can be set to meet the various needs.

● has by MMI, round MMI automatic correction features to meet the short tail section and more bends demand.

● cam drivers available cylinders / hydraulic choice may shift mode control cylinder / servo selection.

● 8.4 / 10.4 英寸 640 × 480,800 × 600 color TFT LCD graphic display, 3D graphics, multi-language menu-driven operator interface.

● configure the USB interface, available U-disk backup / upgrade system software, available U-disk backup / restore processing program and machine parameters.

● Configuring Ethernet networking group can control, remote monitoring, remote diagnosis, remote maintenance, network DNC.

● 32 ~ 512 digital inputs, digital outputs from 32 to 512 can be directly connected to the sensor signal and solenoid valves, simple and reliable.

● Rich protection: stop, hard limit, soft limit, the driver alarm, light curtain protection, motor overheating, oil temperature is too high alarm.